box gluing machine price

The Evolution of Box Gluing Technology

Box gluing technology holds a significant position within the packaging industry and has undergone substantial evolution over time. Initially, the process of gluing boxes was heavily reliant on manual labor. Workers would manually apply adhesive and assemble the cardboards to form boxes. This method was not only time-consuming but also limited in terms of productivity. However, as technology advanced, the processes for box gluing became significantly automated, with the development of machines that increased production speed and efficiency.

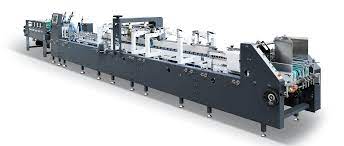

Modern box gluing and forming machines are complex systems capable of operating at high speeds, gluing thousands of boxes per hour. These machines allow for easy adjustments to accommodate boxes of different sizes and designs, making it easier for manufacturers to meet a variety of customer demands. Moreover, advanced adhesive application techniques used in modern machines ensure that the boxes are more durable and reliable.

Technological advancements have also brought significant improvements in areas such as energy efficiency and sustainability. The latest generation of box gluing machines consumes less energy and reduces waste, thereby minimizing environmental impact. Furthermore, more precise adhesive dosing systems optimize the use of adhesive, leading to cost savings.

The evolution of box gluing technology is shaping the future of the packaging industry. Continuous improvements in machinery will lead to further automation of production processes and enhance packaging quality. These advancements offer manufacturers more flexible, efficient, and environmentally friendly production options while promising consumers more robust and reliable packaging solutions. Therefore, the future of box gluing technology is not only about speed and efficiency but also closely linked to sustainability and innovation.