Box Gluing Machines: Streamlining Packaging Processes for Enhanced Efficiency

Introduction: In the manufacturing sector, efficiency in the packaging process is crucial for maintaining productivity and meeting market demands. Box gluing machines have become essential tools in this respect, automating the adhesive application process and significantly speeding up the assembly of boxes. This article explores the functionality, advantages, and applications of box gluing machines, highlighting how they contribute to optimizing packaging lines.

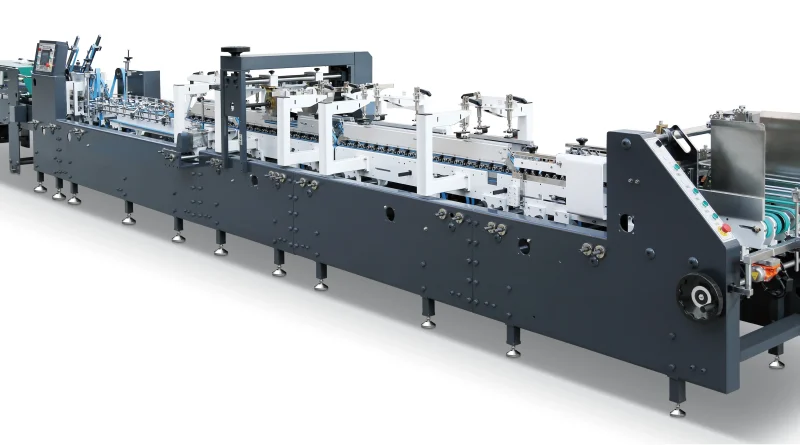

What is a Box Gluing Machine? A box gluing machine is a specialized piece of equipment designed to automate the process of applying adhesive to various types of boxes and cartons. Typically used in the packaging industry, these machines ensure precise glue application, which is crucial for producing strong and durable boxes. They can handle a range of materials, including cardboard and corrugated fiberboard, with configurations suitable for different box designs and production requirements.

Operational Features:

- Precision Glue Application: Box gluing machines are engineered to apply the perfect amount of adhesive, ensuring consistent bond strength across all boxes.

- High-Speed Operation: Designed for efficiency, these machines can process thousands of boxes per hour, significantly reducing assembly time.

- Flexibility: They accommodate various box sizes and styles, making them suitable for diverse packaging needs. Modern machines often feature quick setup changes, minimizing downtime between different production runs.

- Automation: Advanced sensors and programming allow for automated operation, reducing labor costs and human error.

Benefits of Box Gluing Machines:

- Enhanced Productivity: By speeding up the gluing process, these machines enable manufacturers to increase output, thereby meeting higher production targets and improving turnaround times.

- Consistent Quality: Automated gluing helps maintain a uniform standard of box assembly, which is essential for ensuring product safety during shipping and handling.

- Cost Efficiency: Automating the gluing process reduces the need for manual labor, thereby cutting operational costs and enhancing overall profitability.

- Reduced Waste: Precise glue application means less adhesive waste, contributing to cost savings and more environmentally friendly operations.

Applications Across Industries:

- E-commerce: Ideal for assembling shipping boxes that need to be robust and secure, as these are critical for protecting goods during transit.

- Food and Beverage: Used in packaging for food products where box integrity can affect product freshness and shelf life.

- Pharmaceuticals: Ensures that medicinal products are securely packaged to prevent contamination and comply with industry regulations.

- Consumer Electronics: Applies to packaging sensitive electronics, which require sturdy boxes to protect against impact and moisture.

Conclusion: Box gluing machines are indispensable in the modern packaging landscape, providing a fast, reliable, and cost-effective solution for assembling boxes. As companies continue to look for ways to enhance efficiency and reduce costs, the adoption of advanced gluing technology plays a critical role. Whether for small-scale operations or large industrial setups, box gluing machines offer substantial advantages, driving improvements in productivity and ensuring high standards of packaging quality. As the demands of the packaging industry evolve, these machines will remain key components in the quest for operational excellence and customer satisfaction.