“Empowering Modern Packaging: Unveiling the Latest Technological Innovations and Future Perspectives in Box Gluing Machinery”

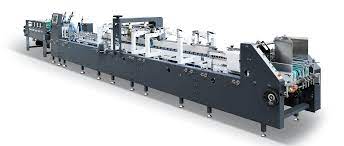

Box gluing machinery plays a pivotal role in the modern packaging industry, providing the essential service of efficiently sealing boxes to ensure product safety during transport and storage. As the market demands quicker turnaround times and more sustainable practices, the technology behind box gluing machinery has significantly advanced. This article explores the latest innovations in box gluing machinery and their impact on the packaging sector.

Technological Advancements in Box Gluing Machinery

- High-Speed Automation: Today’s box gluing machines are designed for high-speed operation, capable of handling large volumes of boxes with precision at unprecedented speeds. This increase in speed is achieved through enhanced motor capabilities and better synchronization of mechanical components.

- Precision Glue Application Systems: Modern machines incorporate sophisticated glue application systems that precisely control the amount of adhesive used, minimizing waste and ensuring a strong, clean bond. These systems often use sensors and AI algorithms to adjust glue flow in real-time based on box material and size.

- Integrated Quality Control Systems: Newer models of box gluing machinery come equipped with integrated quality control systems that use cameras and sensors to instantly detect and reject boxes with improper sealing. This automation not only improves overall product quality but also reduces the need for manual inspection.

- Flexible and Modular Designs: Flexibility is key in contemporary box gluing technology, with machines now featuring modular designs that can be easily adjusted or upgraded to handle different box sizes and types. This adaptability allows manufacturers to quickly switch between projects without significant downtime.

- Sustainability Focus: Addressing environmental concerns, the latest box gluing machines are more energy-efficient and designed to work with eco-friendly adhesives. Manufacturers are increasingly focusing on reducing the carbon footprint of their machinery.

Impact on the Packaging Industry

The advancements in box gluing technology have several significant impacts on the packaging industry:

- Enhanced Production Efficiency: The automation and speed of modern box gluing machines enable manufacturers to meet the growing demands of various industries, significantly cutting down production time and labor costs.

- Improved Product Reliability: With precise glue application and integrated quality control, the reliability of packaged goods increases, leading to lower return rates and higher customer satisfaction.

- Greater Flexibility: The ability to quickly adapt machinery to different specifications allows for a broader range of packaging solutions, making it easier for companies to customize their packaging to specific product needs.

- Sustainability: By reducing waste and using less energy, these machines support the industry’s shift towards more sustainable practices, which is increasingly important to consumers.

Future Trends

The future of box gluing machinery looks toward even greater integration of AI and machine learning to optimize glue usage and speed based on real-time feedback and predictive analytics. Furthermore, the ongoing development of biodegradable and smarter adhesives promises to enhance the sustainability of the packaging process even further.