What is Box Gluing Machinery? Enhancing Efficiency in Packaging Operations

In the dynamic world of packaging, efficiency and durability are paramount. Box gluing machinery plays a pivotal role in this setting, automating the process of sealing boxes to ensure they are ready for distribution. This machinery is essential for businesses looking to optimize their packaging processes with speed, accuracy, and reliability. This article explores the fundamentals of box gluing machinery, its operational mechanics, and its importance across various industries.

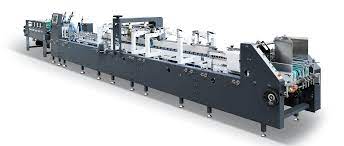

Definition and Functionality of Box Gluing Machinery

Box gluing machinery, also known as a carton gluer, is industrial equipment designed to apply adhesive to the seams of cardboard or corrugated boxes in a fast and uniform manner. These machines are capable of handling various box designs, from simple straight-line boxes to more complex multi-point glued cartons. The primary function of these machines is to distribute glue accurately along predetermined box flaps and then precisely fold and press these flaps to form a complete, sturdy package.

Technological Features

Modern box gluing machines incorporate several advanced features to ensure optimal performance:

- High-Speed Automation: These machines are designed for high-speed operations, allowing for rapid production lines that can significantly boost output.

- Precision Glue Application: Automated systems ensure a precise amount of glue is applied to each joint, reducing waste and preventing weak bonds.

- Flexible Configuration: Many box gluers can be quickly reconfigured to accommodate different box sizes and styles, making them ideal for facilities that handle a variety of packaging needs.

Operational Benefits

The integration of box gluing machinery into a packaging line offers numerous advantages:

- Increased Production Efficiency: Automation speeds up the gluing process, enabling businesses to meet high production demands swiftly.

- Enhanced Product Consistency: Machine precision ensures each box is glued with consistent quality, enhancing the integrity of the packaging and reducing the risk of product damage during shipping.

- Cost Reduction: By automating the gluing process, these machines reduce labor costs and minimize glue waste, leading to significant savings.

Applications Across Industries

Box gluing machinery is vital in multiple sectors that rely on efficient packaging solutions:

- E-commerce: Rapid and reliable box assembly is crucial to meet the fast-paced demand of online shopping.

- Pharmaceuticals: Ensures secure and durable packaging to maintain the integrity of health products.

- Food and Beverage: Used in packaging operations where sturdy and hygienic packaging is necessary to ensure product safety and freshness.

- Consumer Electronics: Provides strong and protective packaging for delicate electronic products.

Future Trends

The future of box gluing machinery is likely to see further innovations in automation and materials technology. Developments may include smarter sensors and AI-driven systems that can automatically adjust gluing parameters for optimal efficiency and minimal waste. Additionally, as sustainability becomes more critical, there is a growing trend towards machines capable of working with eco-friendly adhesives and recycled materials.

Conclusion

Box gluing machinery is an indispensable tool in modern packaging operations, providing the speed, consistency, and reliability needed to maintain a competitive edge in the market. As technology advances, these machines will continue to evolve, playing a crucial role in the future of industrial packaging by driving efficiency and embracing sustainable practices.