Skip to content

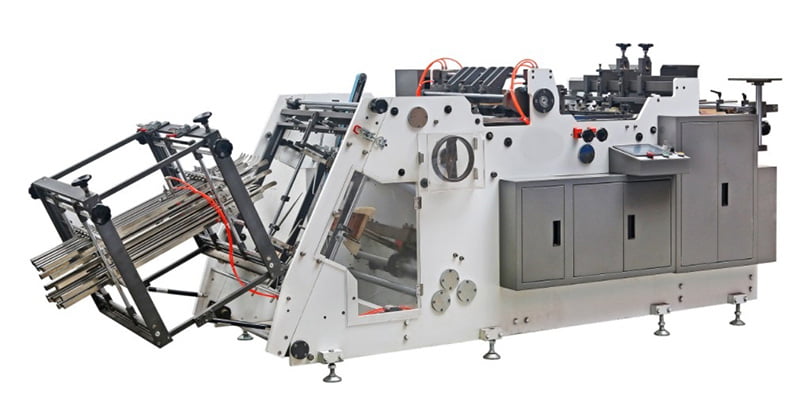

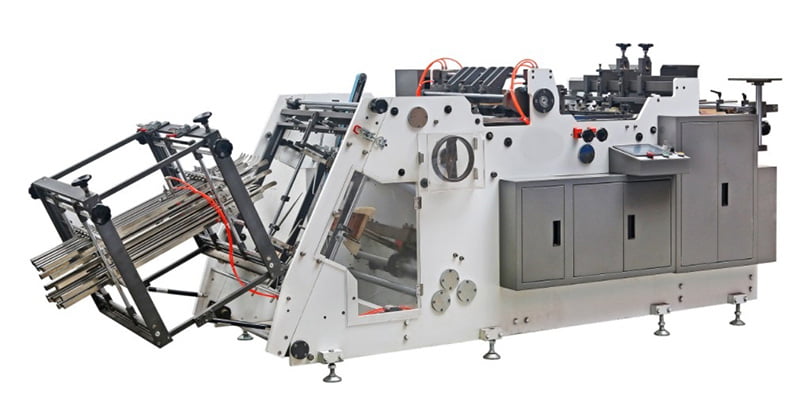

In an industry where precision, efficiency, and innovation are key, the evolution of box gluing machinery through augmented reality (AR) and artificial intelligence (AI) stands out as a pioneering leap towards the future of packaging technology. This groundbreaking integration is not only redefining the capabilities of box gluing machines but also setting new standards for operational excellence and customization. This article delves into how AR and AI are transforming box gluing machinery, heralding a new era of smart manufacturing in the packaging sector.

- Augmented Reality for Enhanced Precision and Training:

- Augmented reality technology introduces an interactive visual layer to the box gluing process, guiding operators with real-time, 3D visual cues. This AR guidance system ensures unprecedented precision in glue application, drastically reducing errors and material waste. Moreover, AR facilitates immersive training experiences for operators, significantly shortening the learning curve and enhancing safety by simulating various operational scenarios without the risks associated with real-life training.

- AI-Driven Predictive Maintenance:

- Artificial intelligence transforms maintenance from reactive to predictive, utilizing machine learning algorithms to analyze historical operation data and predict machinery failures before they occur. This predictive maintenance capability minimizes unplanned downtime, extends machinery lifespan, and optimizes maintenance schedules, ensuring that box gluing machines operate at peak efficiency.

- Customization at Scale with AI Algorithms:

- AI’s advanced algorithms enable box gluing machinery to automatically adjust to varying box dimensions and designs in real-time, facilitating a high degree of customization. This adaptability allows for efficient small-batch production runs with minimal setup time, catering to the growing demand for personalized packaging solutions without compromising on speed or cost-effectiveness.

- Quality Control Reinvented with Machine Learning:

- Machine learning models, trained on vast datasets of quality metrics, are revolutionizing quality control in box gluing operations. These models can instantly detect and correct deviations in glue application, box alignment, and adherence to specifications, ensuring that each box meets stringent quality standards. This automated quality assurance process reduces the reliance on manual inspection, enhancing overall productivity and product consistency.

- Optimized Operational Efficiency through AI Analytics:

- The integration of AI into box gluing machinery extends beyond the machine itself, encompassing the entire production ecosystem. AI-driven analytics provide insights into operational inefficiencies, energy consumption patterns, and workflow bottlenecks. Leveraging these insights, manufacturers can streamline processes, reduce energy costs, and increase throughput, propelling the box gluing sector towards lean manufacturing principles.

- Sustainable Manufacturing with AI and AR:

- In line with global sustainability efforts, AI and AR technologies contribute to more environmentally friendly box gluing operations. By optimizing glue application and reducing material waste, these technologies ensure that packaging processes have a smaller environmental footprint. Additionally, AI’s operational efficiency enhancements contribute to lower energy consumption, aligning with the industry’s sustainability goals.