Box Gluing Machine: A Catalyst for Cost Savings in Packaging Operations

In the dynamic and competitive landscape of the packaging industry, efficiency and cost-effectiveness are pivotal for businesses aiming to thrive. The advent of box gluing machines has emerged as a game-changer, offering substantial cost savings alongside operational excellence. This article delves into how these innovative machines optimize packaging processes, underscoring their significant impact on reducing expenses.

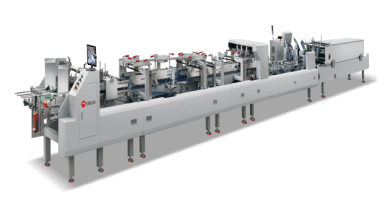

Introduction to Box Gluing Machines

Box gluing machines automate the process of applying adhesive to cardboard or corrugated box flaps, facilitating seamless and secure sealing. By replacing manual gluing tasks, these machines streamline production lines, enhancing both speed and precision. Their capability to accommodate various box sizes and styles with minimal adjustment times further amplifies their utility in diverse packaging environments.

Direct Reduction in Labor Costs

The most immediate benefit of integrating box gluing machines into packaging operations is the significant reduction in manual labor requirements. Manual box assembly and gluing are labor-intensive, time-consuming, and prone to errors, leading to higher operational costs and potential waste. Automation not only accelerates the process but also diminishes the likelihood of human error, ensuring a consistent output quality that translates into cost savings.

Material Efficiency and Waste Reduction

Box gluing machines are engineered for precision, applying the optimal amount of adhesive with each application. This precision mitigates waste associated with overuse of glue, a common issue in manual operations that can lead to increased material costs and potential product damage. Furthermore, the consistency ensured by automated gluing enhances the structural integrity of boxes, reducing the need for rework or additional packaging materials to secure products during transportation.

Enhanced Productivity and Throughput

The automation of gluing tasks enables packaging operations to scale their output without a proportional increase in labor costs. Box gluing machines operate at speeds that far exceed manual capabilities, thereby significantly boosting production throughput. This enhanced productivity allows businesses to meet higher demand volumes, improve lead times, and capitalize on market opportunities more effectively, all while maintaining a lean operational cost structure.

Operational Flexibility and Scalability

Adapting to market demands and varying product sizes can be challenging with manual packaging processes. Box gluing machines offer the flexibility to quickly switch between different box designs and sizes, minimizing downtime and enhancing responsiveness to customer needs. This adaptability is crucial for businesses looking to expand their product range or adjust to seasonal fluctuations without incurring significant additional costs.

Long-Term Return on Investment (ROI)

While the initial investment in a box gluing machine may be significant, the long-term cost savings and operational efficiencies provide a compelling ROI. Reduced labor costs, material savings, increased productivity, and the ability to adapt to changing market demands contribute to a rapid payback period. Moreover, the durability and low maintenance requirements of these machines ensure sustained benefits, solidifying their role as a cost-effective solution for packaging operations.

Conclusion