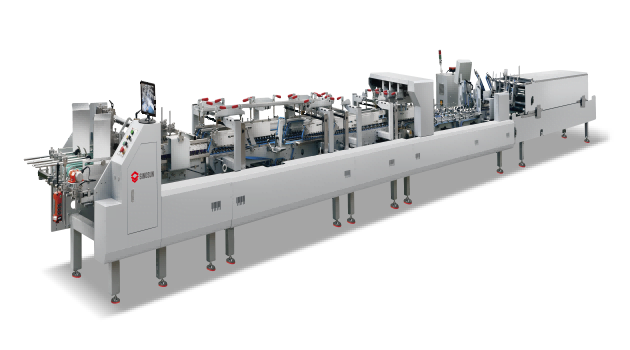

Box gluing machinery, which plays a crucial role in the packaging industry, has witnessed a remarkable evolution due to technological advancements. These innovations aim to improve efficiency, sustainability, and customization, addressing the rapidly changing needs of the modern market.

Integration of Advanced Robotics

The latest generation of box gluing machines incorporates advanced robotics to enhance precision and speed. Robotic arms, equipped with sensors and end-effectors, can now accurately apply glue on complex patterns and surfaces, ensuring consistent quality across all products. This automation reduces manual labor, lowers the risk of errors, and significantly speeds up the production process.

Eco-Friendly Adhesive Solutions

In response to the increasing demand for sustainable packaging solutions, new box gluing machinery is designed to work with eco-friendly adhesives. These adhesives, including water-based and bio-based options, offer strong bonding without harmful emissions. Machinery advancements also focus on minimizing glue waste and enhancing the efficiency of glue application, contributing to a greener production process.

Smart Machine Learning Algorithms

Smart technology, particularly machine learning algorithms, is revolutionizing box gluing machinery. These algorithms analyze data from the production process to optimize machine settings in real-time, reducing glue consumption and improving bond quality. Predictive maintenance features, powered by machine learning, anticipate machinery issues before they occur, minimizing downtime and extending machine life.

IoT Connectivity for Enhanced Efficiency

Internet of Things (IoT) connectivity is another significant technological advancement in box gluing machinery. IoT-enabled machines can be monitored and controlled remotely, providing real-time insights into production metrics and operational efficiency. This connectivity facilitates quick adjustments to the production process, improving response times to market demands and enabling seamless integration with other production line machinery.

Augmented Reality for Operator Training and Maintenance

Augmented reality (AR) technology is being introduced into the box gluing machinery sector to assist with operator training and maintenance. AR can overlay digital information onto the physical machine, guiding operators through setup processes and troubleshooting steps. This innovation enhances safety, reduces errors, and improves the overall efficiency of the production line.