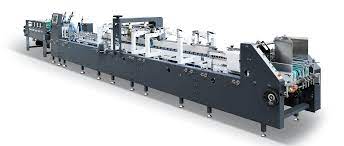

Box gluing machinery, a pivotal component in the packaging industry, has undergone significant advancements, reshaping the production of various types of boxes, from simple cartons to complex, high-strength packaging. These innovations not only enhance operational efficiency but also contribute to sustainability efforts and meet the growing demands for customization.

Enhanced Efficiency through Automation

Modern box gluing machines are epitomes of automation, capable of handling vast quantities of materials with precision and speed. They are designed to operate with minimal human intervention, reducing the likelihood of errors and increasing production rates. The integration of programmable logic controllers (PLCs) and touchscreen interfaces allows for quick setup and adjustments, making it easier to switch between different box designs and sizes without significant downtime.

Sustainability in Gluing Processes

Sustainability has become a crucial factor in the packaging industry, and box gluing machinery has adapted accordingly. Today’s machines are more energy-efficient and can work with eco-friendly adhesives, including water-based and hot-melt options that provide strong bonds without harmful emissions. Additionally, advancements in machine design minimize adhesive waste, further reducing the environmental impact.

Customization and Flexibility

As the market demands more personalized and innovative packaging solutions, box gluing machinery has evolved to offer greater flexibility. Advanced machines now support a wider range of materials and box designs, accommodating everything from lightweight, delicate items to heavy, durable goods. This adaptability enables manufacturers to cater to specific customer requirements, providing bespoke packaging solutions that enhance brand value and customer satisfaction.

Smart Technology Integration

The incorporation of smart technologies, such as IoT (Internet of Things) connectivity and artificial intelligence, into box gluing machinery represents a significant leap forward. These technologies enable real-time monitoring and analytics, optimizing the gluing process for efficiency and quality. Machine learning algorithms can predict maintenance needs and adjust operations to prevent downtime, ensuring continuous production flow.

Future Outlook

The future of box gluing machinery looks promising, with ongoing technological innovations driving the industry forward. The next generation of machines is expected to be even more efficient, versatile, and sustainable, utilizing advancements in robotics, material science, and data analytics. As the packaging industry continues to evolve, box gluing machinery will play a critical role in meeting the complex demands of manufacturers and consumers alike.

In conclusion, the advancements in box gluing machinery are a testament to the packaging industry’s commitment to innovation, sustainability, and customer satisfaction. As technology continues to advance, we can anticipate further improvements that will enhance the efficiency, environmental friendliness, and customization capabilities of box gluing processes, solidifying its role as a cornerstone of modern packaging production.