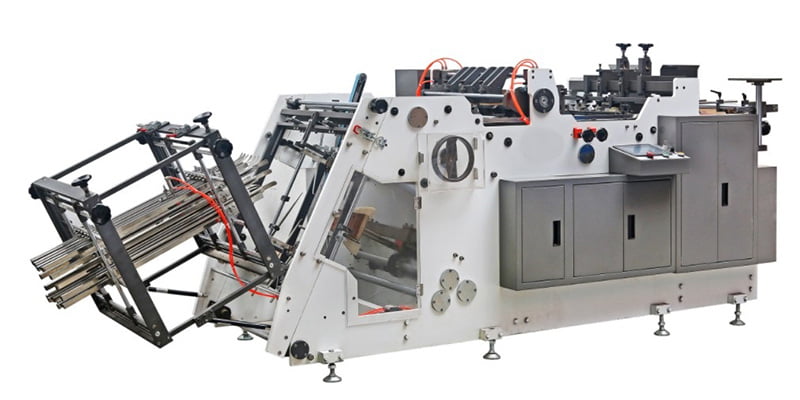

Embracing Efficiency: The Transformative Impact of Box Gluing Machinery on Packaging Operations

Introduction:

In an era where operational efficiency and sustainability are paramount, box gluing machinery has emerged as a transformative solution for the packaging industry. This innovative technology streamlines the assembly process of packaging boxes, offering a leap in productivity and precision. This article delves into the multifaceted benefits and the pivotal role of box gluing machinery in modern packaging operations, marking its significance in an increasingly competitive market.

Operational Efficiency Unleashed:

Box gluing machinery automates the adhesive application process, ensuring fast, consistent, and reliable box assembly. This automation significantly reduces the time and labor traditionally required for manual gluing, allowing packaging plants to scale up their production rates without compromising quality. The precision of machine-applied glue minimizes waste and ensures a stronger bond, enhancing the durability of the final product.

Adaptability and Customization:

Modern box gluing machines are designed with flexibility in mind, capable of accommodating a wide range of box sizes, styles, and adhesive types. This adaptability allows packaging companies to meet diverse client requirements with ease, from simple cartons to complex, multi-part designs. Programmable settings and quick setup features enable rapid changeovers between runs, further boosting operational efficiency.

Sustainability at Its Core:

Sustainability is a critical consideration in today’s packaging industry. Box gluing machinery contributes to greener packaging solutions by optimizing adhesive use and reducing material waste. Moreover, the compatibility with eco-friendly adhesives aligns with the increasing demand for sustainable packaging options, helping businesses to lower their environmental footprint.

Enhanced Safety and Working Conditions:

By automating the gluing process, box gluing machinery also improves safety and working conditions in manufacturing facilities. It eliminates the risks associated with manual gluing operations, such as exposure to toxic adhesives and the potential for repetitive strain injuries. This focus on employee well-being can lead to higher job satisfaction and productivity.

Cost-Effective Production:

Investing in box gluing machinery can result in significant cost savings over time. The reduction in manual labor, combined with increased production speed and material efficiency, lowers overall production costs. These savings can then be passed on to customers or reinvested into the business, driving growth and competitiveness.