“Revolutionizing Packaging Automation: Advanced Technologies and Sustainable Practices in Modern Box Gluing Machinery”

The latest innovations in box gluing machinery focus on increasing the precision and speed of the gluing process while minimizing adhesive waste. Modern machines are equipped with sophisticated application systems that precisely control the amount of glue applied, reducing both excess waste and the risk of weak bonds. Additionally, many systems now feature quick-setup capabilities, allowing operators to switch between different box sizes and styles with minimal downtime.

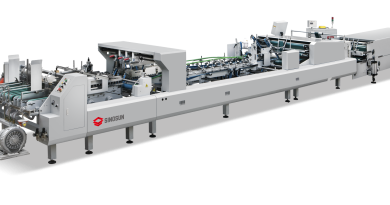

Enhanced Efficiency Through Automation: Automation plays a crucial role in the evolution of box gluing machinery. Today’s machines include advanced robotic systems and conveyor integrations that streamline the entire packaging process from assembly to gluing. These automated systems are designed to maintain a consistent throughput, irrespective of operator skill, ensuring high-quality results at all times. Furthermore, the integration of AI technologies allows for real-time adjustments and troubleshooting, which significantly boosts overall operational efficiency.

Integration with Quality Control Systems: Another critical advancement is the integration of quality control systems directly into the gluing machinery. Cameras and sensors continuously monitor the gluing process, instantly detecting and correcting any deviations in glue application or box alignment. This integration helps prevent the production of defective boxes, thereby reducing waste and improving customer satisfaction.

Sustainability and Material Innovations: Sustainability is a driving factor in the development of new box gluing technologies. Manufacturers are increasingly opting for eco-friendly adhesives that provide strong bonds without harmful emissions. In parallel, the machinery itself is designed to be more energy-efficient, often operating on reduced power modes that do not compromise performance. Additionally, there is a growing trend towards using biodegradable and recycled materials in the production process, which the latest gluing machines are fully equipped to handle.

Challenges and Solutions: Despite significant progress, challenges such as the high initial cost of advanced machinery and the need for ongoing maintenance and operator training persist. To address these issues, manufacturers are developing more user-friendly machine interfaces and offering comprehensive service packages to ensure smooth operation post-installation.

Conclusion: The box gluing machinery sector continues to evolve, driven by the demand for more efficient, precise, and sustainable production methods. As manufacturers continue to innovate, the capabilities of these machines expand, promising further improvements in packaging quality and production efficiency. This ongoing advancement not only benefits manufacturers but also contributes to broader environmental goals by reducing waste and energy consumption.