Understanding Box Gluing Machines: Revolutionizing Packaging Operations

Introduction: In the dynamic world of packaging, efficiency and reliability are paramount. Box gluing machines, crucial components in modern packaging lines, are designed to automate and streamline the adhesive process of box assembly. This article explores the functionality, benefits, and industrial applications of box gluing machines, highlighting their role in enhancing production efficiency and product integrity in various sectors.

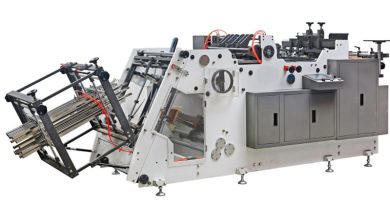

What is a Box Gluing Machine? A box gluing machine is a specialized device used to apply adhesive to areas of cardboard, paperboard, or other material types to assemble boxes and other packaging forms efficiently. These machines vary in complexity from manual to fully automated systems, each tailored to specific production volume needs and operational scales.

Key Features and Technologies: Box gluing machines are equipped with advanced features that ensure precise glue application and consistent box production. Key features typically include:

- Automated Feeding Systems: These systems automatically feed the material into the machine, maintaining a continuous production flow and reducing manual labor.

- Precision Glue Applicators: Precision is critical in glue application. Modern machines use sophisticated applicators that accurately apply the right amount of glue, reducing waste and preventing issues like warping or improper seals.

- Fast Set-up and Changeover: Many box gluing machines are designed for quick setup and easy changeovers, accommodating different box sizes and styles with minimal downtime.

- Quality Control Mechanisms: High-end models incorporate sensors and other quality control mechanisms that detect and reject defective boxes, ensuring only products meeting quality standards proceed down the line.

Benefits of Using Box Gluing Machines: The integration of box gluing machines into packaging operations offers multiple benefits:

- Increased Production Speed: Automation speeds up the box assembly process, significantly boosting production rates compared to manual gluing methods.

- Enhanced Consistency and Quality: Automated gluing ensures uniform application, which enhances the structural integrity and appearance of the final product.

- Reduced Labor Costs: By automating the gluing process, companies can reduce the workforce required for box assembly, lowering operational costs.

- Improved Workplace Safety: Using machines for gluing reduces the risk associated with manual operations, such as repetitive strain injuries and exposure to toxic adhesives.

Industrial Applications: Box gluing machines are versatile tools used across various industries, including:

- Electronics: Ensuring protective packaging for delicate products.

- Food and Beverage: Providing sturdy and reliable packaging solutions that meet hygiene standards.

- Pharmaceuticals: Securing sensitive products in tamper-evident packaging.

- Cosmetics: Crafting attractive packaging that enhances brand value.

Conclusion: Box gluing machines are indispensable in the packaging industry, offering a blend of speed, efficiency, and quality that manual processes cannot match. As manufacturers continue to seek ways to optimize their operations, the role of these machines becomes increasingly vital. Whether for small-scale businesses or large-scale industrial applications, investing in a reliable box gluing machine can significantly enhance operational efficiency and product quality, positioning companies for success in competitive markets.