The Critical Role of Box Gluing Machines in Efficient Packaging Solutions

Introduction: In the evolving landscape of industrial manufacturing, the efficiency of the packaging process plays a crucial role in determining overall productivity. Box gluing machines, specialized equipment designed for the automated application of adhesives on boxes, have become indispensable in enhancing the speed and quality of packaging lines. This article provides an overview of box gluing machines, detailing their operation, benefits, and importance in modern packaging systems.

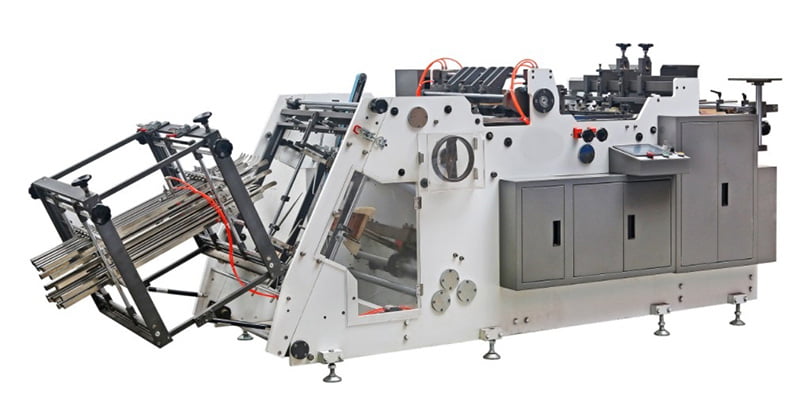

Understanding Box Gluing Machines: Box gluing machines automate the process of applying glue to cardboard and other material sheets to assemble boxes efficiently. These machines are integral to packaging operations, providing a high-speed method for producing ready-to-use packages with consistency and precision.

Operational Mechanics: A typical box gluing machine includes several key components:

- Input and Feeding System: This mechanism automatically feeds flat box blanks into the machine, where they are precisely aligned for the application of glue.

- Gluing System: Utilizing either rollers or spray nozzles, this system applies a controlled amount of adhesive to specific areas of the box blank, according to preset patterns.

- Folding Section: After gluing, mechanical folders shape the box by bending the cardboard at the scored lines, forming the box structure.

- Compression and Setting Unit: This final stage ensures that the glue sets correctly, with pressure applied to the glued joints to solidify the box’s construction.

Advantages of Using Box Gluing Machines: The integration of box gluing machines into a packaging line offers numerous advantages:

- Enhanced Production Efficiency: Automating the gluing process significantly speeds up production, enabling the rapid assembly of boxes.

- Superior Product Consistency: Machine precision eliminates human error, ensuring each box is uniformly constructed for a professional appearance and reliable function.

- Cost Reduction: Automated processes reduce labor costs and minimize glue waste, contributing to more economical production cycles.

- Versatility: Advanced models of box gluing machines can handle a variety of box designs and sizes, adaptable to changing production requirements.

Industrial Applications: Box gluing machines are utilized across multiple sectors where packaging is a critical component of the product delivery system, including:

- Consumer Electronics: For secure packaging of fragile items.

- Food & Beverage: In creating strong and hygienic packaging suitable for consumables.

- Pharmaceuticals: Ensuring that packaging meets strict industry standards for safety and containment.

- Cosmetics and Personal Care: Where attractive and durable packaging enhances consumer appeal.

Conclusion: Box gluing machines are fundamental to the modern packaging industry, providing essential capabilities that enhance the speed, quality, and cost-effectiveness of packaging operations. As industries continue to seek improved efficiency and product safety, the role of these machines in automating and refining packaging processes becomes increasingly vital. With ongoing advancements in technology, box gluing machines are set to offer even greater benefits, making them a key investment for manufacturers aiming to optimize their production lines.