“Sealing Success: How Cutting-Edge Technology is Transforming Box Gluing Machinery”

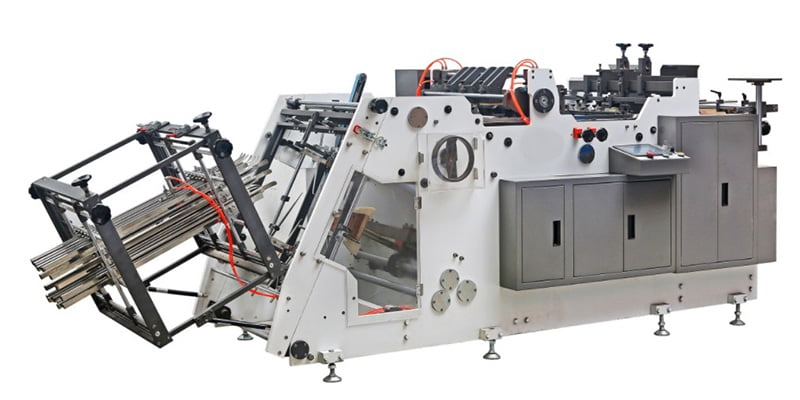

In the dynamic world of packaging, the efficiency and reliability of box production are paramount. Box gluing machinery, essential for assembling various types of packaging, has seen transformative technological improvements that increase productivity and adaptability in manufacturing processes.

Integration of Robotic Automation

One of the most significant advancements in box gluing machinery is the integration of robotic systems. These robotic systems enhance precision in glue application, ensuring consistent quality across thousands of boxes. Robots can adjust on the fly to different box sizes and styles, making the machinery versatile and capable of handling custom orders with ease.

Smart Control Systems

The adoption of smart control systems, such as touch screen interfaces and PLCs (Programmable Logic Controllers), has modernized the operation of box gluing machines. Operators can now input specifications and adjustments with greater accuracy, minimizing human error. These systems also enable real-time monitoring and adjustments during production, optimizing the gluing process and reducing downtime.

Sustainability and Material Innovation

Technological advancements in box gluing machinery also focus on environmental impact. Modern machines are designed to work efficiently with eco-friendly adhesives and recycled materials. This compatibility helps manufacturers meet increasing regulatory and consumer demands for sustainable packaging solutions.

Predictive Maintenance through IoT

The integration of IoT (Internet of Things) in box gluing machinery is a game-changer. IoT allows for predictive maintenance, where the machinery can alert operators about potential issues before they lead to breakdowns. This predictive capability ensures continuous operation and longevity of the machinery, reducing repair costs and production halts.

Quality Assurance with Vision Systems

Advanced vision systems are now part of box gluing machinery, providing high-resolution imaging to inspect glue patterns and box integrity. These systems can identify and reject products that do not meet quality standards, ensuring that only the best packaging reaches the market.

In conclusion, the technological enhancements in box gluing machinery are pivotal for the packaging industry. These innovations not only boost efficiency and quality but also support sustainability and adaptability to diverse packaging needs. As technology continues to evolve, box gluing machinery will remain at the forefront of packaging innovation, meeting the industry’s demand for reliable and high-quality production.